Maintenance and repair of Miraphone brass instruments

Introduction

Dear Valued Customer,

Congratulations on the purchase of your new, high-quality, handcrafted Miraphone Instrument!

The longevity of your brass instrument depends greatly on the regular care and maintenance given particularly to the moveable components of the instrument which are the valves, triggers and slides.

Since new instruments do not contain any moisture in the tubing, it is advisable to first rinse the tubing out with clear lukewarm water. This will not only enhance the playability, but will protect the insides from corrosion. After every playing session, be sure to empty any saliva or condensation from the instrument by removing and emptying valve slides. If possible, leave the instrument out of the case or gig bag until it has had a chance to dry out.

This pamphlet summarizes the important care and maintenance steps for your instrument. Should further questions arise, please do not hesitate to get into touch with a qualified Miraphone dealer or contact Miraphone directly. We believe strongly in our products and their quality and trust

that you may encounter many years of enjoyment in playing your Miraphone instrument.

Musically Yours,

The Miraphone Team

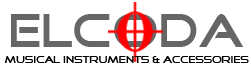

Valve and lever system diagrams

1 - Tuning slide trigger; 2 - Minibal screw; 3 - Stop arm; 4 - Miraphone-Minibal linkage rod; 5 - ATV-valve; 6 - Long bearing with bore hole; 7 - Valve casing; 8 - Adjusting pin; 9 - Valve casing; 10 - Short bearing with bore hole (remove screw cap); 10a - Ventillager unten (kein ATV-Ventil); 11 - Screw cap; 12 - Valve; 13 - Upper screw cap; 14 - Valve casing; 15 - Trigger axel; 16 - Ball bearing.

Trombone maintenance diagrams

17 - Outer slide; 18 - Inner slide; 19 - Stocking.I. Valve Maintenance

Regularly care for the valves using the enlosed oils.

Lubricating ATV-Valves on the Bearing Pin

Lubricate the valve bearings by applying oil first to the upper bearing pin (6) and then to the lower bearing pin by removing the bottom screw cap (11) on the lower bearing (10) and applying the oil through the small pin hole on the bearing pin.

Lubricating Rotary Valves on the Bearing Pin

Lubricate the valve bearings on the upper bearing pin (6) under the stop arm and the lower bearing pin by removing the screw cap (11) on the bearing pin (10a). Caution: Be careful not to use too much oil. Excessive oil could leak into the valve casing slowing the action and causing valves

to become sluggish. Oil the valves and bearings with Miraphone Pin Oil.

Removal and Replacement of ATV-Valves

• In order to remove the inner valve casing (7) from the outer valve casing (9), first remove the Minibal screw (2) from the stop arm (3) using the Torx screw driver. Hold tightly onto the Minibal linkage when turning the screw since the valve is under tension due to the trigger spring.

• Remove the lower screw cap (11).

• Hold the valve (5) from above and push it out through the top.

• Rinse the valve (5) with lukewarm water and clean the valve casing (9) with a non-abrasive cleaning cloth (D). Apply a thin film of grease (Selmer Tuning Slide Grease) on the valve casing (9). It is best to rub the thin layer of grease on with your fingers.

Take care that the grease does not get into the valve during removal and replacement.

• Simple and precise re-fitting of the valve casing is ensured by the adjusting pin (8).

• Now screw the lower valve cap (11) onto the outer valve casing (9) and insert the Minibal screw (2) through the Minibal-linkage (4) back into the stop arm (3).

Valves and casings (9) are important components of the instrument; take care that you go slow in order to prevent damage to them.

A rotary valve instrument that is in frequent use, does not usually need to be oiled. Should the instrument sit for a longer period of time without being played, the valves should then be oiled to prevent them from freezing up.

In this case, rinse the instrument with lukewarm water and then simply put a few drops of valve oil (Fast Oil Nr. 02) into and through the second valve in the valve section. Spread the oil into the valve by tipping the instrument and simultaneously operating the valve keys. Be sure not to wash slide grease into the valve section with the fast oil. Valve bearings, however, should be oiled at regular intervals (as described previously).

Oiling Piston Valves

The following procedures should be completed before and after playing the instrument:

• Remove the upper screw cap (13) of the valve casing (14) and carefully pull the valve (12) out. Take care not to turn the valve (12) while removing.

• Evenly distribute 2-3 drops of Fast Oil onto the valve.

• Re-insert the valve and screw the valve cap (13) back on.

• Be sure to line the valve (12) up straight before inserting it into the outer casing (14).

• Work the valves up and down rapidly to evenly distribute the oil over the surface.

• Oil the valves again after playing. This protects the valve from oxydation and prolongs the life of the instrument.

Monthly cleaning of Piston Valves and Valve Casings (14)

• Remove debris on the valves with a non-abrasive cloth (D).

• Carefully wrap the cleaning rod (C) with the cleaning cloth (D) making sure that no metal is exposed.

• Remove any dirt from inside the inner valve casing (14).

Valves and casings (14) are important components of the instrument; take care that you go slow in order to prevent damage to them.

II.Valve Section Maintenance

Oil the trigger axle (15) and the ball bearing (16) of the Miraphone Minibal-linkage (4) with Miraphone pin oil. Allowing the joints to become too dry will cause unnecessary wear-and-tear.III. Maintenance of Valve Slidesand Tuning Triggers

• Once every 3 months or so, take out the valve slide and remove all grease and debris using the cleaning cloth (D).• Rinse the slide with lukewarm water and dry thoroughly.

• Evenly distribute Miraphone slide grease onto the valve slides.

• Special tuning trigger oil should be used for the tuning triggers (1).

• Replace all slides.

IV. Mouthpiece Cleaning

Rinse the mouthpiece out with lukewarm water and clean interior using the mouthpiece brush (E).V. Interior Cleaning

Regularly rinse instrument with lukewarm water by running clear water directly through the valves. After rinsing, begin maintenance procedures on all moving parts according to steps I, II and III as prescribed in this pamphlet. Make sure that all neoprene and cork bumpers (in the horseshoe stoppers) and spit valves are intact.VI. Lacquer Care

Remove debris on the surface of the lacquer using a non-abrasive cleaning cloth (D) and the La Tromba Lacquer Care (B). For silver or gold plated instruments, us a silver or gold polish (available at specialty retailers and hardware stores). Do not use conventional polishes for cleaning the surface of your instrument. These could cause damage to the lacquer. Take care not to scratch the lacquered surface with objects such as rings, watches or belt buckles.VII. Trombone Slide Maintenance

Carefully extract the slide and wipe it down with the cleaning cloth (D). It is recommended to use lukewarm water and the Slide-O-Mix Cleaning Kit for routine cleaning of the slide. Dry the inner (18) and outer slide (19) well after wet cleaning and reassemble before proceeding.Application of Slide-O-Mix

•Put one large drop from the small bottle onto the stockings (19) of the inner slide (18). Pull the outer slide (17) up and down a few times to distribute liquid evenly.

• Apply some liquid from the large bottle onto the inner slide making it run down along the length (for about 10 cm). Again, distribute the liquid by operating the slide.

• Use a spray bottle to spray water onto the inner slide (18). Re-spray as often as needed. Miraphone recommends the Slide-O-Mix spray bottle to complete this kit. Do not dry after spraying.

Due to usage and aspects of design, each slide may need slightly different care. Over time, you will discover how much of which lubricant works best for your instrument.

It is not necessary to remove the old Slide-O-Mix film before re-lubricating as long as the slide is not dragged by dust or dirt.

VIII. Accessories

Care Products

In an effort to provide ease and support for a maintenance routine, Miraphone has compiled a selection of the most important care items.

Illustration of Care Products:

A - Care Kit Bag; B - La Tromba Lacquer Care; C - Cleaning Rod; D - Cleaning Cloth; E - Mouthpiece Brush; F - Miraphone Slide Grease; G - Fast Oil; H - Miraphone Pin and Bearing Oil; I - Torx Screw Driver

Replacement Parts

Over time and under frequent useage, certain parts of your brass instrument may succomb to normal wear-and-tear. Should individual parts become a necessity, you should use quality replacements from Miraphone.

Your official music dealer will usually have the most common replacement parts for your brass instrument in stock. Specialty parts can be ordered by the dealer direct through Miraphone and can be usually sent out on short notice. The advantage of using official Miraphone replacement parts is that they fit ”like a glove“ thereby shortening repair waits by avoiding complications and adjustments.

Gig Bags and Hard Cases

Miraphone's no-compromise approach to quality is also evident in our extensive line of gig bags and hard cases. Miraphone’s bags and cases are specially designed to optimally protect and safeguard their valuable contents.

Our gig bags and hard cases ensure safe and practical transport as well as the well-protected storage of your Miraphone brass instrument.

Illustration of Gig Bags and Hard Cases:

J - Gig Bags; K - Hard Cases

IX. General Information

Be sure to never carry the instrument by the thumb ring.Allow the instrument time to dry out after playing or cleaning to prevent the onset of corrosion. Remove any excess condensation after playing.